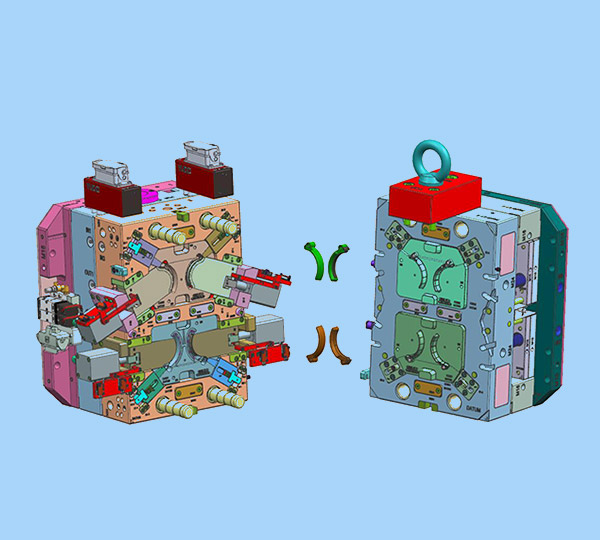

Transfer molds or two-shot molds are designed with two or more plastic resins and

colors in a single operation to make custom plastic components. RYDTOOLING

2-component injection molds are made of high-quality raw materials and can be

used across different applications and industries.

Transfer molding is a process where a two-shot injection is used to produce custom plastic parts with two or more plastic resins of different colors in a single operation for a specific function. The main aim of this process is to create products with better structural integrity for a wide range of uses.

RYDTOOLING has been around for close to 15 years, amassing valuable experience through those years that puts us in the correct position to handle all your transfer mold needs. We have a team of qualified experts who are well versed with all the two-shot injection molding techniques. You are assured of getting exactly what you need.

Your B2B needs are also well covered by our services. At RYDTOOLING, we understand the importance of forging partnerships and the challenges of running a business. We offer good discounts on bulk purchases for our most loyal clients to help them hit the road running. Continued support is the core of our business.

Being the best in the industry doesn’t come by luck; we have invested in technology and state-of-the-art machinery to ensure our clients get the very best for their manufacturing needs. Working with us opens you up to some of the following advantages

Our design team is one of the best you will ever come across. We don’t just focus on the functionalities and performance of the transfer molds; we also make sure they look their best because we understand the image is everything.

We are always in touch with our clients through the whole designing process, incorporating the feedback along the way to give a complete end product that checks all the boxes. Doing things halfway is not how we do things at RYDTOOLING. We commit to a project to the end.

The transfer molds from our assembly lines have all the attributes needed to make them work as efficiently as advertised. The good drips on the molds allow you to use them in a wide range of applications, depending on your needs.

You get the best value for your money through the use of our versatile products that can be used in different ways. Creating versatile tools is our biggest motivation as we are driven by the need to create convenient solutions for our clients.

We don’t cut corners with the raw materials or the manufacturing recess. We go over and beyond the minimum industry standards to create strong and long-lasting transfer mold products that will last you ages.

Our transfer molds are among the most sought after in the industry and are used in many different kinds of industries including:

Electrical components that require complex mechanical and electronic segments can use two shot molds to create these components.

Parts of the car that require plastic components in two different colors can be made using transfer molds of different shapes and sizes.

All appliances need some plastic components that are not only functional but have cosmetic appeal as well. 2k molds can help create these parts.

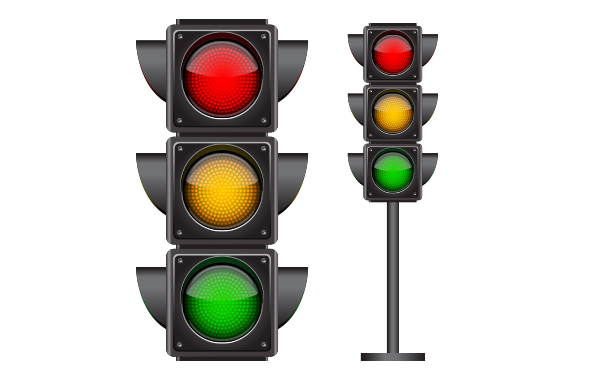

Medical equipment, streetlights, and various consumer products require thermoplastic components that can be manufactured using transfer molds.

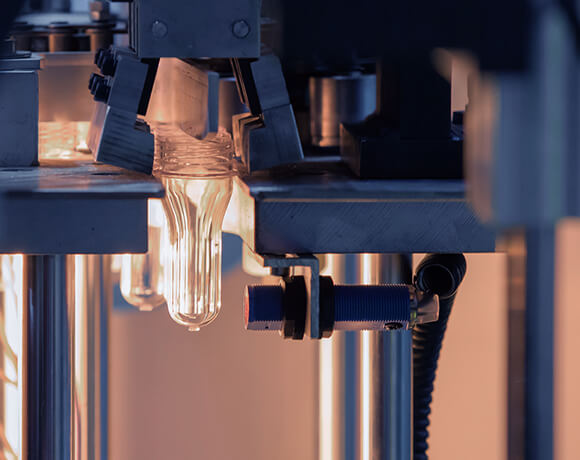

Transfer molding process allows you to use a single tool to fabricate several components. This automation process reduces the operational costs, and the need for labor also goes down significantly. 2k injection molding process involves piping thermoplastics inside the mold and heating them, waiting for them to cool and then taking the finished product out.

RYDTOOLING multi-color injection molding begins with concept design and renderings of the component you want to manufacture. Next we use rapid prototyping and 3D printing to show you what your design will look like in real life. Based on your critique we tweak the design and create a 2K mold that matches your requirements exactly. Finally, we use our 14 injection molding machines ranging from 86 tons to 1,600 tons to provide plastic injection molding services to make all kinds of different components.

Thermoplastics are the backbone of any transfer molding process. The process of transfer molding requires heating the plastic components again and again without damaging the integrity of the material. This is why the quality of thermoplastics used in 2k molding is very important.

At RYDTOOLING we use the highest quality thermoplastics and other raw materials to ensure that the two-shot molds stand the test of time and use. Our rigorous quality checks at all stages of the injection molding process ensure that our end product is error-free.

Improved product appeal

Fulfilled complex designs

Enhanced grip on non-slip surfaces

Capable of extra functions

Stronger and more durable

Wide applications

Our customer from Australia obtained a project from the local government to develop a traffic light lens. This special lens is called Fresnel Lenses whis has lots of saw-tooth feature. RYD has never made such a product before, but we are going to look for the solution. We have seen similar traffic light on the street, we are sure that it is made by injection molding. The critical point is that how to make the saw-tooth feature on the lens.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!