Source:https://www.pinterest.com/pin/513903007474565140/.

Injection molding is a production technique that enables the large-scale production of items. It operates by injecting molten elements into a mold. It’s usually used to make dozens of identical things as part of a large manufacturing procedure. Metals, glasses, elastomers, and confections are among the materials used in injection molding, but thermoplastic and thermosetting polymers are the most frequent.

In this article, we are going to cover the basics of injection molding engineering, what it is, what it involves and the pros and cons of injection molding. Keep reading to find out more!

How Does It Work?

Source:https://www.pinterest.com/pin/665547651169882789/.

The creation of the mold is the initial step in injection molding. Most molds are finely machined from metal, usually aluminium or steel, to suit the aspects of the product they will manufacture.

The material for the part is injected into a heated barrel and combined using a helical curved screw after the mold has been made by the mold maker. The substance in the barrel is melted by heating bands, and the liquid metal or plastic is then injected into the mold cavity, where it chills and solidifies to match the mold’s structure.

The use of chilling lines that disseminate water or oil from an exterior temperature controller helps shorten the cooling period. Mold tools are installed on plate molds, which separate once the substance has solidified and remove the item from the mold using ejector pins.

A two-shot mold is a type of injection molding that allows different materials to be blended into one component. This method can be used to provide plastic items with a softer feel, to colour a part, or to create objects with varied performance capabilities.

Single-cavity or multiple-cavity molds are available. Each cavity of a multiple cavity mold might have similar pieces or be distinct to generate parts with diverse geometry. Owing to the injection and clamping forces, aluminium molds are not recommended for high volume manufacturing or products with tight dimensional forbearance since they have poor mechanical qualities and are vulnerable to wear, distortion, and breakage. Steel molds are more robust than aluminium molds, but they are also more costly.

The structure and characteristics of the component, the materials for the component and the mold, and the attributes of the injection molding machine all demand careful design in the injection molding procedure.

What Factors are Considered in Injection Molding?

1. Monetary

Source:https://unsplash.com/photos/lVFoIi3SJq8.

Considering the expense of the machinery and the molds themselves, the startup expense for injection molding manufacturing can be quite high.

2. Manufacturing Volume

Source:https://unsplash.com/photos/RF5HrKt8pfk.

To evaluate whether injection molding is the most expense-friendly production process, you must first establish how many components you want to make.

3. Aspects in the Designing

Source:https://unsplash.com/photos/o2TRWThve_I.

Injection molding is made easier by reducing the number of components and streamlining the shape of your items. Furthermore, the mold tool’s design is critical for preventing faults throughout manufacturing.

4. Cogitations for Manufacturing

Source:https://unsplash.com/photos/1MHU3zpTvro.

Manufacturing will be aided by reducing cycle time and using machines with hot runner molds and well-planned-out tooling. Slight adjustments and the usage of hot runner technologies can result in significant cost reductions for your components. Minimizing assembly needs will also save money, particularly if you’re manufacturing tens of thousands or even millions of pieces.

What are the Different Mold Types Used in Injection Molding?

Source:https://unsplash.com/photos/IHZYwmTGnUc.

- Cold Runner Molds

Source:https://www.pinterest.com/pin/807903620641066754/.

Cold runner molds, which enter the part via sprues and runners, are a good example of more traditional tooling. This is the most basic variant, however, it may result in greater waste and longer working cycles. Depending on the usage, a large number of waste products can be crushed and reprocessed again for future use, although this may compromise the resin’s physical properties.

When dealing with more sophisticated, expensive materials such as engineering and medical-grade resins, or when regranulation isn’t a possibility, a more cost-effective hot runner mold may be the best choice.

2. Hot Runner Molds

Source:https://www.pinterest.com/pin/420312577732171550/.

In hot runner tools, a temperature-controlled manifold is used to dramatically reduce or eliminate runner scrap from the cycle. Injection points can be found on the outside or interior of the part. Since the sprue or runner system is often a critical component of the mold cycle, this can significantly speed up the process. Furthermore, detaching the runner saves money by reducing waste.

A temperature controller for the press in which hot runner molds are used is required, with the controller being designed to meet the mold’s manifold. A hot runner tool has greater mold protraction costs, but material and cycle time savings frequently pay for it in the long term. This is particularly true for applications requiring large annual quantities or expensive engineering-grade adhesives.

3. Family Molds

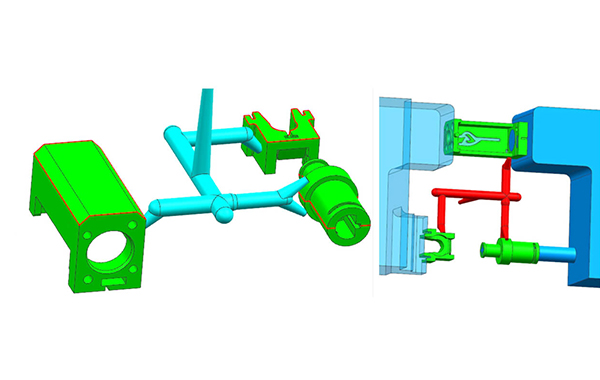

Source:https://www.pinterest.com/pin/638244578442522803.

A family mold has one mold base but two or more unique cavities, allowing for the production of two or more discrete pieces. Shut-offs can be used to isolate production to specific cavities, or all of the elements can be created simultaneously time.

For best molding results, the components should be equal in size, shape, adhesive, and predicted volumes, especially if all components will be formed at the same time. Automation may be required to separate the parts during or after manufacturing.

If mold cost is a major concern and volume is low, a family mold might provide cost savings and versatility.

4. Unscrewing Molds

Source:https://www.pinterest.com/pin/633178028847576815/.

Unscrewing molds is the most common way to make weaving holes in a plastic product. Miniature drive mechanisms are incorporated into the technique, spinning threaded sections to remove subvert features from these molds. Threads can be employed on the inside or outside, and the extraction is timed to meet the press cycle.

With multi-shot / multi-model tooling, a design engineer can use two or more different substances on the same part in the same cycle. Unique resources may be desired for a variety of reasons, including physical characteristics or just look. In these molds, many manifolds are usually employed. Multi-shot tooling is a lovely option for high-end items, and it can also be used to switch colours within a product line.

4. Two/Three Plates Molds

Source:https://www.pinterest.com/pin/35465915804052383/.

Cold runner molds are three-plate molds with a third plate added to the runner system, allowing you to position your injection point practically somewhere else on the tool. Although this is less expensive than constructing a hot runner system, this type of mold usually has large, bulky runners that are harder to handle.

5. Low/High Cavitation Molds

Source:https://www.pinterest.com/pin/964544445163561324/.

Single cavity molds make one item per cycle. Because they are inexpensive to create, they are a cost-effective solution when part volumes are low. In addition, they have a quicker turnaround time. The disadvantage of molding production is a higher component part cost.

Molds with many cavities produce a higher number of elements per cycle. The main advantages are increased capacity and lower item part costs, as even more parts can be created simultaneously.

Why is Injection Molding Used? (Advantages)

Source:https://unsplash.com/photos/m-HZ2aex1so.

The propensity to expand manufacturing in large quantities is the main benefit of injection molding. The cost per unit throughout injection molded production is exceptionally low once the startup costs have been covered. As more parts are made, the price tends to drop dramatically.

The following are some additional benefits:

1. Production of Low-Cost Scrap Rates

Source:https://unsplash.com/photos/xoU52jUVUXA.

Injection molding has a low scrap rate compared to traditional production procedures such as CNC machining, which removes large portions of a plastic block or sheet. Nonetheless, when compared to additive production technologies like 3D printing, which have even lower scrap rates, this can be a disadvantage.

Note that waste plastic from injection molding is released from four places: the sprue, the runners, the gate sites, and any overflow substance that spills out of the component cavity itself (a situation known as “flash”).

A sprue is just the route that transports liquid plastic from the injection molding machine’s nozzle to the injection mold device’s access point. It’s a distinct component from the mold tool. A runner is a series of passages that connect with the sprue and guide the liquid plastic into the part cavities inside the mold tool, mostly within or as a component of the mold tool. Finally, after the runner, the gate is the segment of the channels that leads straight into the segment cavity.

After an injection mold cycle, which takes only seconds, the liquid plastic cools completely, producing solid plastic in the sprue, runners, gates, and component cavities, as well as a little amount of overflow on the margins of the components, if the seal isn’t perfect.

2. Injection Molding is a Very Reproducible Process

Source:https://unsplash.com/photos/TE_fvX7fhD8.

That is, the second portion you make will be nearly identical to the first, and so on. When it comes to maintaining brand continuity and part dependability in high-volume manufacturing, this is a fantastic feature.

3.Scale-up Production

Source:https://unsplash.com/photos/yoPOtxc0s6c.

Being up to the task to generate a vast number of components on a large scale The cost of production is quite inexpensive once the initial costs of design and molds have been financed. As more components are created, the cost of manufacturing decreases.

What are the Downsides of Injection Molding?

Source:https://unsplash.com/photos/J59wWPn09BE.

1. Injection molding has a hefty upfront cost, especially when it comes to tooling. A prototype part must be created first prior to any pieces being produced. After this is accomplished, a prototype mold tool must be built and tested. It takes time and money to finish all of this, and it may be an expensive procedure.

2. Injection molding isn’t suitable for making huge components in one piece, either. This is due to the general size constraints of injection mold machines and mold tools, this is the case. Items that are too large to fit into an injection molding machine must be made in many portions and then assembled later.

3. The third downside is that extensive undercuts necessitate skilled design and can increase the cost of your project.

Conclusion

Injection engineering still remains to be an essential part of major industries. At RYD, we are driven by quality provision and customer satisfaction. Reach us for any inquiries and we’ll be happy to assist you. All the Best!