Insert Molding Process Step by Step

It is dangerous to make use of components after they’ve been manufactured without encasing them with plastic. It’s essential to encase these components to make

Share

Share

There are so many types of plastic materials that are actively used in molding processes around the world. Plastics are preferred due to their malleability, low melting points, availability, and the flexibility to be turned into just about anything. Among the many raw materials, there are two that stand out, acrylic and nylon. They are among the most commonly used raw materials when it comes to all forms of plastic injection molding.

We are going to look at the differences, the similarities, and the individual qualities that make each of these materials stand out. We will also briefly explore their strengths and weaknesses in the hope that by the end of this, you will be able to make an informed decision if you are faced with a choice of either.

Source: Pinterest

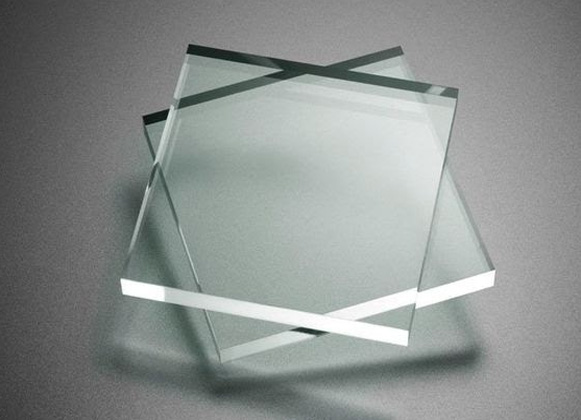

Acrylic is one of the most unique plastic materials used in a number of plastic molding processes. It is a clear element that is compatible with a number of colors, meaning the appearance can be altered to any color that you may wish. Acrylic was developed in 1941 and has been used in different capacities since then, undergoing changes and improvements over the years.

Strong and Durable: Acrylic may not look like it, but it is as strong as glass, but unlike glass, it goes a step further by having a stronger bond, meaning that it cannot shatter easily. This flexibility and durability makes it the perfect material for making household products.

It is inexpensive: Making and accessing acrylic, despite its good qualities, is cheaper than most of the other raw materials used for molding of plastic. It is cheaper than glass, easier to cut, easier to modify, and this is why you will always find some of it in any mold-making factory.

Easier Processing: Acrylic is flexible, and this makes it easy to bend it, saw, mill, drill, glue, polish, or engrave without spilling any other part. This flexibility adds to the many qualities that increase its value in manufacturing circles.

Transparent: The transparency offered by acrylics increases the range of the things it can be used for. It has a 92% transparency rating, which is as clear as any plastic can get, and it can be used to make packaging materials as well as lenses for goggles and LCD screen protectors.

Safer: Being tougher, flexible, and transparent, acrylic is much safer when compared to other materials like glass. It doesn’t break which means the chance of walking over sharp shards is down to zero. This is what is used for making aquarium glazing, among many others.

Prone to Scratches: What it packs in flexibility and versatility, it lacks in the ability to be blemish-free. Any sharp object that comes into contact with acrylic leaves scratches and other dents, and without constant cleaning, it may lose its good appearance.

Low Heat Resistance: Tough as it may be, acrylic should never be used to make products that will be used actively for handling the heat. They will deform and eventually melt when exposed to heat for a long time, and this will make them unusable.

Recycling Difficulties: Acrylic, like most other plastic-based products, is not good for the environment. It can be repurposed for other uses as it is, but it cannot be easily recycled as that will cost even more than the initial manufacturing.

Source: Pinterest

Also known as Polyester, nylon is one of the most widespread materials in the plastic world as it is easy to make and has many properties that allow it to be used for an unlimited number of products. Nylon has been around for so many years, and with each generation, a newer version of it is produced with better qualities that make manufacturing easier. The following are some of the pros and cons.

Lightweight: Nylon is very light. This is due to the low density it has after being refined from petroleum products. This makes it ideal for making daily used products that can be moved around and carried easily.

Abrasion Resistant: Nylon is able to resist scratches and light dents because of its flexible nature. Unlike acrylic, which tends to have a brittle nature, nylon is able to yield to pressure and regress back to the original shape once the pressure is withdrawn.

Good Insulator: Nylon can be fashioned into any shape and size and can be used for insulation purposes as it doesn’t conduct any heat or electricity. You will find it in mass use in electronic industries.

Prone to Static: Nylon is highly prone to ecstatic energy. When there’s close contact between nylon and another foreign body, there’s static electricity produced, and this can cause discomfort.

Picks up Oils: Oils tend to stick to nylon much faster than other materials, and getting rid of them takes time and special materials, which is another added cost.

Sensitive to Heat: Nylon is very sensitive to heat, and it can shrink and even melt when exposed to extreme heat, even for a few seconds; this can affect the structural integrity of the product.

Not Eco-Friendly: Nylon is one of the biggest polluters in the world due to how they are produced in mass numbers. They are literally everywhere, from packaging to clothes. They take too long to degrade, and this has caused a serious environmental hazard.

Pricey: The production may be cheap, but when you consider the cost it has on the environment and how it costs twice to recycle it than to make it, then you have a material that, despite all the benefits it brings, ends up costing more in the long run.

Making a decision between nylon and acrylic is not that hard since there’s very little that separates the two. However, it all comes down to what you intend to make. There are some products that will come good if made with nylon and others with acrylic. To understand the science behind this, check out our website and get all the questions you may have answered by our experts.

It is dangerous to make use of components after they’ve been manufactured without encasing them with plastic. It’s essential to encase these components to make

Transparent plastic is being used in virtually every industry and this is because of its capacity to allow you see through and its ease of

Plastic is a common material used in the production of objects that can be used in homes, the automobile industry, and virtually all sectors. It

Basically, there are two kinds of plastics – thermoplastic, and thermosets. But the majorly talked about kind is the thermoplastic because of its versatile and

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!