The injection molding process is used by different businesses in various industries for the manufacture of different products. This process features great accuracy and diversity that is greatly appreciated by people in business looking to manufacture products. For instance, if you are looking for plastic products, there are different raw materials to work with. You have the option of either going with thermoplastic polymers or thermoset polymers. This choice is dependent on your specific needs and what you want your products to achieve.

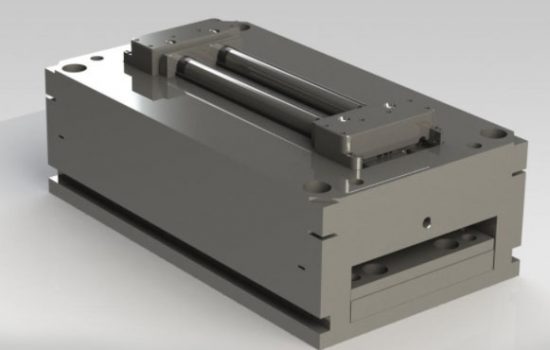

Additionally, with injection molding, you have the option of choosing between the three types of injection molding machines. They include hydraulic IMM, electric IMM, and hybrid IMM. These machines feature different advantages that are applied in different situations. All this goes to show that injection molding is a process worth investing your time and resources in. Working with a quality injection molding manufacturer is essential to ensure that they guide you through this process accurately. Now the big question remains how much you should spend on injection molding.

Source: https://rexplastics.com

As you’ve seen the injection molding process will feature a few different factors to ensure that the process is accurate. This is essential for the quality of products that will be produced and to build great customer relations. However, the most pressing concern for most businesses is the need to have a clear understanding of the costs they will incur. When it comes to calculating the cost of injection molding, you’ll find that different factors will come into play. To determine the price, the needs and specifications of the customers have to be taken into consideration. Additionally, once that is determined, the next thing is to consider the different costs of other important injection molding aspects. Some of the costs that you will encounter include:

Injection molding is a process that can only be executed with the use of an injection molding machine. As discussed earlier, there are different types of injection molding machines that can be used in this process. This goes to show that the prices will differ depending on the specific machine that will be in use. The injection molding machine cost will vary depending on the feature that comes with the machine. For instance, with the hybrid IMM, the price associated is higher compared to the other types of machines. This is mainly because the hybrid machine is essentially a combination of hydraulic and electric machines. This means that you get to enjoy the best of both machines in one which can prove to be more expensive.

Source: www.ennomotive.com

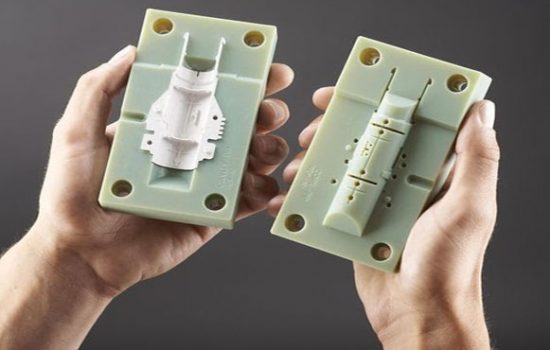

The cost of the plastic injection mold you’ll be working with will vary depending on several factors. In this, you’ll consider the size of your mold, the material you’ll use, and the number of items you’ll be producing. After these considerations, you will be in a position to figure out how much the mold you want to use would cost. For example, if you’re dealing with machine washers and need them mass-produced, the first step is to make a mold.

If you are working with a capacity of 1000 washers, then you can estimate the value of the mold to come in at $1000 to $2000. This price is quite low given that the mold that will be designed and made will be used over and over for as many products as you wish to purchase. The best part is that with most companies, you can keep these molds with them for later use which negates the need to pay for a new mold.

On the other hand, if you were working on producing video gamepads, the setup would be different. For this, you’d probably need 12 molds to work together simultaneously on the front section, the back, and the buttons. This setup will result in an additional cost ranging from $100 to $80,000. With this, the price goes up given that you are working with multiple molds at a time that needs to be designed and made in 3 different designs.

This shows how the cost of an injection mold varies greatly depending on the product for which it is made. It’s important to remember that the prices mentioned above can vary depending on the manufacturer you’re working with. They’re just a ballpark figure for how much an injection mold of your product could cost. Additionally, you need to keep in mind that the price of the injection mold will also vary depending on whether you’re using single cavity or multi-cavity tools. With the single cavity, the price will be significantly lower compared to the multi-cavity molds.

Source: https://industrytoday.com

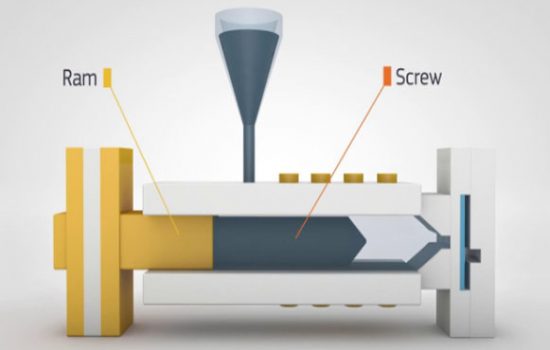

As we discussed earlier the raw materials used in injection molding are divided into two, thermoplastic polymers and thermoset polymers. These plastic materials are designed to work well with this process and are offer quality on products manufactured. In both the thermoset and thermoplastic polymer groups, various types of plastic resins may be used. There will feature the use of different materials that have a wide range of characteristics and applications. This makes it essential to have a thorough understanding of the materials that are ideally suited for your product.

In determining the overall injection molding cost, the injection molding material will come into play and influence that total cost greatly. You need to understand that the different materials featured in both polymer groups will come with a different price tag. Some plastic resins will be cheaper compared to others. This is mainly dependent on the specific characteristics you want your plastic resin to present. For instance, if you’re dealing with a material that has chemical resistance as well as other features, the price would be higher. However, if you’re going with a standard material that doesn’t have any extra features, the cost would be lower. The material you choose to work with will determine your cost per part in the production. This is important to keep in mind to ensure that you are working with a budget that will offer you great quality.

Source: https://www.3erp.com

In injection molding when it comes to the labor involved you’ll find that it will be lower since most of it is catered to in the injection mold cost. To get a better understanding of this, the labor that goes into injection molding mainly features mold designing, mold making, and lastly the injection molding process itself. As you can see, the mold design and mold making costs are catered to in the injection mold section. When it comes to the injection molding process itself manual labor is not a major factor that should be considered. This is mainly because the process involves the use of a self-regulating and automated injection molding machine. This goes to show that there is little to no interference apart from the programming of the machine.

Given that it is a repeatable process, the labor cost will not be as high as compared to other aspects mentioned above. Granted, elements like location, type of equipment, and any additional services will add to the cost, it won’t be too high. The cost of labor will be the one thing that will be lower depending on the specific manufacturer you work with.

The price of injection molding will vary depending on the manufacturer you work with and the different aspects featured in the manufacturing process. Ensure that you work with a quality injection mold manufacturer who will not be high priced. Additionally, ensure that you pay attention to the value you are getting to ensure that you fully customize the manufacturing processes.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!