Source:https://www.pinterest.com/pin/579275570825784667/.

Designing plastic parts is a difficult undertaking that involves a number of elements that must be addressed in order to meet the app’s needs. How will the component be used? How does it interact with the other components in the assembly? What kinds of loads will it be subjected to when it’s in use? Manufacturing issues, in addition to functional and structural concerns, play a significant influence in the design of an injection-moulded plastic part.

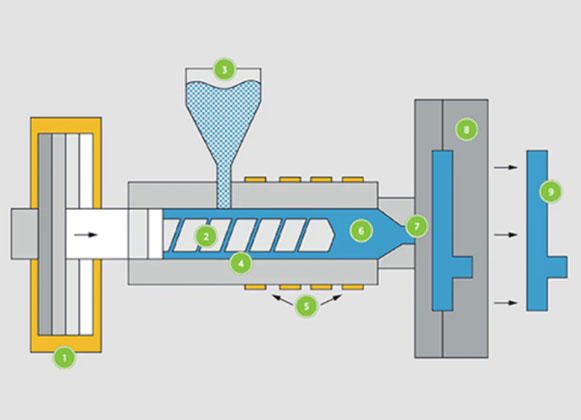

The shape of the components in the part is mainly determined by how the molten plastic penetrates, fills, and cools inside the cavity to produce the part.

That said, we are going to look at the necessary elements of injection molding designs that you need to know. Keep Reading!

Mold Types for Injection Molding(Plastic)

Source:https://unsplash.com/photos/IHZYwmTGnUc.

1. Family Molds

Source:https://www.pinterest.com/pin/638244578442522803.

A family mold has one mold foundation but two or more distinct cavities, enabling two or more separate pieces to be produced. All of the components can be manufactured at the same time, or shut-offs can be employed to isolate manufacturing to specific cavities. The pieces should be identical in size, shape, adhesive, and expected volumes for best molding outcomes, particularly if all components will be molded at the same time. Separating the parts during or after manufacture may necessitate automation.

A family mold can give cost reductions and adaptability if mold cost is a driving issue and volume is modest.

2. Unscrewing Molds

Source:https://www.pinterest.com/pin/633178028847576815/.

The most frequent method of producing woven holes in a plastic object is to unscrew molds. Miniature drive mechanisms (rack & pinion, electric, or hydraulic motors) are integrated into the procedure and spin threaded parts to extricate subvert features in these molds. Interior or exterior threads can be used, and the extraction is timed to match the press cycle.

A design engineer can utilize two or more distinct substances on the same part in the same cycle with multi-shot / multi-model tooling. Distinct resources may be desirable for a number of reasons, including distinct physical attributes or just appearance. Multiple manifolds are frequently used in these molds. Multi-shot tooling is a beautiful solution for sophisticated items, and it may also be utilized to change colours within a product category.

Multi-shot tooling necessitates the use of customized presses and molds. It’s possible that many machine nozzles, hot runner systems, and mold rotation will be required.

3. Hot Runner Molds

Source:https://www.pinterest.com/pin/420312577732171550/.

A temp-controlled manifold is used in hot runner tools to drastically decrease or terminate runner scrap from the cycle. Injection sites might be on the exterior or inside of the part. Because the sprue or runner system is often a decisive element in the mold cycle, this can considerably boost cycle times. In addition, removing the runner saves money on wasted material.

Hot runner molds necessitate a temp controller for the press in which they are used, with the controller being tailored to fit the mold’s manifold. A hot runner tool has higher mold continuance costs, but it often pays for itself in the long run by material and cycle time reductions. This is especially true for operations that need huge annual volumes or costly engineering-grade adhesives.

4. Cold Runner Molds

Source:https://www.pinterest.com/pin/807903620641066754/.

Cold runner molds, which use sprues and runners to entrance into the part, are a nice illustration of more conventional tooling. This is the simplest version, however, it may generate more wasted material and lengthier operating cycles. The number of waste products may be ground and processed again for future usage, directly dependent on the application, albeit this may impair the resin’s physical qualities.

When working with more complex, pricy materials like engineering and medical grade resins, or when regrind isn’t an option, a more economical hot runner mold may be the best option for your venture.

5. Insulated Runner Molds

Source:https://www.pinterest.com/pin/1044201863572622060/.

Insulated runner tools imitate standard cold runner molds, but they use cartridge heaters or other heating technologies to build an encircling layer of molten resin, generating an insulated “cull” to mimic the effect of a hot runner system. This method is cheaper(compared to others) than utilizing a hot runner, which necessitates the use of a temp controller, and it also allows for quicker colour and substance adjustments.

Insulated runners, on the other hand, are not appropriate for all substances and, in most cases, do not perform well with more rigorous engineering grade resins.

7. Two/Three Plates Molds

Source:https://www.pinterest.com/pin/35465915804052383/.

Cold runner molds are three-plate molds, but by having a third plate to the runner system, you may place your injection point almost anywhere on the tool. This is generally cheaper than installing a hot runner system, but this sort of mold frequently has enormous, cumbersome runners that are more difficult to operate.

8. Low/High Cavitation Molds

Source:https://www.pinterest.com/pin/964544445163561324/.

One item each cycle is produced by single cavity molds. When part volumes are low, they are an expense-friendly method since they are cheap to produce. They also have a faster turn-around time. In molding manufacturing, the downside is a higher piece part cost.

Molds with several cavities create more components per cycle. Improved capacity and cheaper component part costs are the main benefits, as more parts may be manufactured in the same amount of time.

What Does a Good Plastic Injection Mold Design Have?

1. Drafts

Source:https://www.pinterest.com/pin/64387469662012768/.

One component of mold design that must not be forgotten is the ease with which the final product may be removed from the mold without causing harm to the part’s coating. The walls of the mold are given a draft angle, or taper, to achieve this. The quantity or degree of draft angle is determined by a number of parameters, including the part’s design, material, mold cavity depths, surface quality, texture, and contraction.

The side walls of the mold are usually angled only a few degrees to provide sufficient room for the part to be easily undone when the mold is unsealed. The more draft is necessary, the deeper the hollow must be. Angles of draft commonly range from 1 to 5 degrees.

2. Gates

Source:https://www.pinterest.com/pin/513903007481262137/.

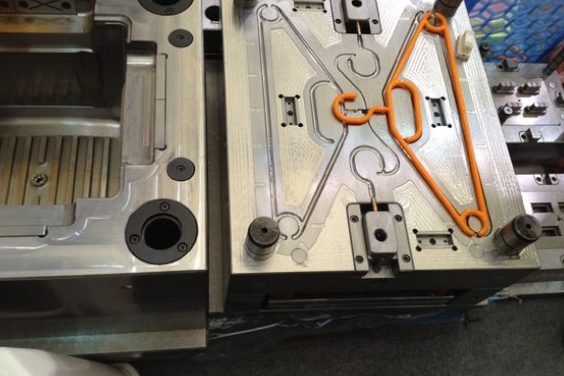

The apertures at the ends of the runners that govern the flow of molten plastic into the mold cavity are known as gates. The dimension and physique of gates varies based on the part design and resin substance. To obtain optimum flow, fill pressures, cooling duration, and tolerance, design engineers must consider a variety of criteria while determining gate types and positions. It’s critical to place gates where they won’t have an effect on the part’s functionality or look.

8. Finish and Texture

Source:https://www.pinterest.com/pin/791648440748738074/.

The surface finish is determined by the cooling of the mold and the cooling of the parts. A smooth surface finish on a 50percent glass-filled resin, for instance, is dependent on temperature management. The component’s exterior must be resin-rich, and the fibreglass must be noticeably thicker in the part, which necessitates a hotter mold—and a ten percent longer cooling time.

Molds can also be constructed to impart a texture or patterning to the mold surface, which can minimize assembly processes by, for instance, imprinting the corporate logo onto the plastic. Texture can also improve product functionality, such as improved grip or less friction wear. Matte, gloss, graphics, grains, logos, and geometric patterns are examples of texture types. A draft may require to be altered to ease component ejection which depends on the type, depth, and placement of texture, which is decided during the mold design procedure.

How to Design a Manufacturing Mold for Plastic Injection in Factory

Source:https://unsplash.com/photos/xj8qrWvuOEs.

Mold design and tooling’s primary purpose is to develop a high-manufacturable product—a high-quality technique that is straightforward and coherent, durable, easy to run and maintain, and matches all customer demands at the lowest feasible cost. The optimal tooling choice for each customer’s needs must be designed to meet these requirements.

Tooling choices must be taken early in the design process to achieve this. To offer a practical machining viewpoint on product design, requested limits, tool design, selected substances, and related costs, the toolmaker must be included as early as practicable. Taking this step ahead of time is the greatest way to avoid wasting time and money on rework, which can add a large amount to the tooling budget. Because part and tool design are interdependent, they should be done at the same time whenever practical.

Clients are always worried about expenses for good reason. After all, tooling is one of the most expensive aspects of the manufacturing process. A highly experienced team of engineers and technical experts using the latest in complex design and manufacturing technology is required to properly design, produce, and use tooling for each item.

Collaborating closely with an expert, efficient tooling team that makes sensible decisions on material selection and design compromises early in the design process helps save labour costs.

What to Review in an Injection Mold Design

Source:https://unsplash.com/photos/NmleJ9Rp8Zs.

The next phase in tool design is assigned to a single person who wraps a tool around the CAD. This individual is in charge of controlling cost, production challenges, and verifying the design remains within the limitations of the intended press size, which has previously been defined by multiple CAD evaluations and talks with team members.

As the tool designer goes over the design, he or she can refer to a tool design checklist. Prior to releasing the finalized tool design to the build shop, it can be recorded and reviewed with diversified manufacturing teams. Procedural engineering, automating, tool maintenance, post-mold operation groups, comprising assembly and secondary teams such as paint and or decorative groups, should all be represented on these teams.

Conclusion

Plastic injection molding plays an integral part in major industries. That is why at RYD, we understand the essence and the detailed procedure of mold design services and offer nothing short of outstanding. If you are looking to invest in plastic molding, Contact us and we’ll be able to help. Best of Luck!