It is extremely advised that mold designs be obtained before beginning to work on any injection mold. These classes are just for mold requirements and do not assure workmanship in any manner.

Buyers must engage with providers whose craftsmanship standards and dependability are widely established. Mold life cannot be assured due to differences in design requirements and mold circumstances. This guide is designed to provide the estimated cycle times for each type of mold, whilst ignoring the abrasion caused by rust, inadequate maintenance, and inappropriate molding techniques.

Classifications of SPI molds span from 101 to 105 molds and injection molding. The classes listed below are suggestions for obtaining quotes before you buy plastic injection molds. Our goal with these categories is to place orders for uniform types of molds. Our goal with these classes is to reduce confusion in the mold quotation system and enhance client satisfaction.

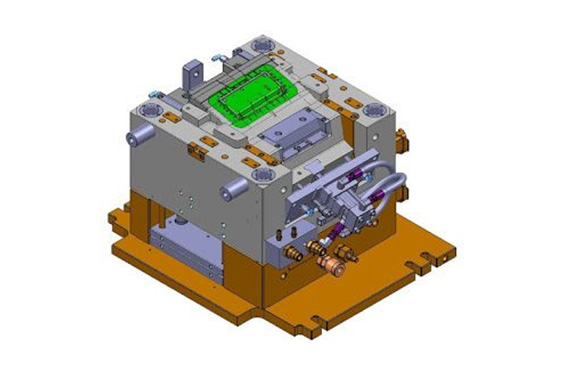

Extremely high volume manufacturing injection tools designed for million-cycle lifetimes. The hardness of the mold foundation should be at least 280 BHN. Molding surfaces (cavities and cores) should be hardened to 48 Rc or above. All additional features, such as slips, heel bars, gibs, wedges, and so on, should be hardened tool steels as well.

Ejection should be controlled. Wear plates are required for slides. Temperature control measures should be included whenever possible in cavities, cores, and slides. Corrosion in the cooling channels reduces cooling efficiency during the life of the mold, lowering component quality and increasing cycle time.

Extremely high volume manufacturing injection tools designed for million-cycle lifetimes. This mold is identical to Type 101 except that guided ejection, reinforced slide wear panels, plated water lines, and wear plated cavities are not needed. The rest of the extras are entirely optional. This tool is suitable for abrasion and/or near tolerance items and has a medium to high output rate.

Medium-volume manufacturing injection tools with lifespan cycles of little more than 500,000. The hardness of the mold foundation should be at least 165 BHN. Components and cavities must have a BHN of 280 or above. All other options are optional.

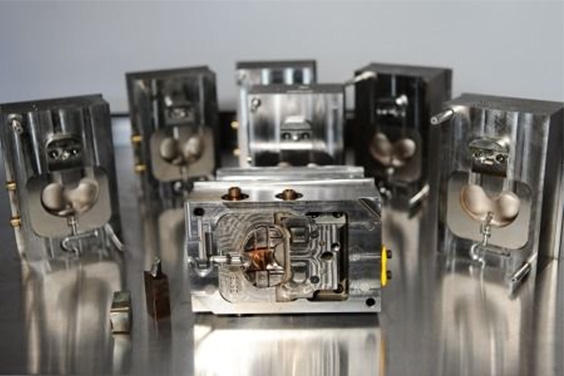

Low-volume manufacturing injection tools with lifespan cycles of no more than 100,000. The mold base can be made of either mild steel or aluminum. Components and cavities can be made of aluminum, mild steel, and every other alloy that has been approved. All other options are optional.

Prototype tools are designed to have a lifespan cycle of no more than 500. The mold foundation can be made of cast metal, epoxy, and every other material that is strong enough to manufacture the bare minimum of prototype parts. This tool is solely for testing purposes. The rest of the extras are entirely optional.

The SPI Mold Categorizations were written and compiled by the United States Society of Plastic Engineers (SPE) who aim to provide a simplified definition of the different thermoplastic injection tools needed for certain manufacturing demands.

These recommendations are meant to be a starting point for future development, either on a project-by-project basis or based on the needs of the client so that they better represent what is expected of a certain tool. The various categories will necessitate variations in tool design, structure, materials, and parts.

Designed for exceptionally high output. This is the most expensive tool, and it is manufactured using just the best materials.

Medium to high production tool that is ideal for abrasive materials and/or items that require precise tolerances. This is a high-quality, reasonably priced instrument.

Tool for medium-scale manufacturing.

A tool with a low output. Only used in restricted quantities, particularly with non-abrasive materials. Price range: low to moderate.

No more than 500: Prototype only. The tool should be built as cheaply as feasible to create a small number of prototype pieces.

Molders and plastic injection mold makers can construct a mold in several methods, from the quick and inexpensive prototype mold to the very high-quality, long-term production mold. The issue is ensuring that everyone involved is “on the same page” when a mold is cited. As previously stated, the Society of the Plastics Industry has established its “Standard” for mold requirements for this purpose.

Ensure the plastic mold factory and company you acquire these services from do adhere to these standards before purchasing any mold products from them.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!