Manufacturing has come a long way and continues to grow in leaps and bounds. There are now thousands of processes that have been invented that make work much easier and faster, and this has improved the quality of products all around. Among the many innovative processes available to manufacturers, molding could be described to be one of the most widely used methods. Breaking this down further, molding comes in varying types, and among them, injection molding is the one that stands out the most.

We are going to look at injection molding processes, why it is a good idea to go with it, how it is tied into manufacturing, the advantages and drawbacks, and the place it will have in the future. If you are a manufacturer looking to switch to this innovative method, stick around to the end to gain some important insights.

Source: Pinterest

This is a process of obtaining molded products by injecting molten plastic materials into a pre-made mold and then subjecting that to a cooling process to solidify them into the final product that you wish them to have. It is an ideal process for the mass production of items that have complicated shapes as it is fast, efficient, and doesn’t cost too much. The process requires the use of an injection molding machine, raw materials, and a mold. There’s a lot of heat involved, and speed is of vital importance since the rate of cooling will determine how the end product will end up being.

The entire injection molding process for a single product is very short, all things considered. On average, it takes between 2 seconds and 2 minutes, depending on the size of the mold. In general, there are four major steps that take place in the injection molding process. They include the following.

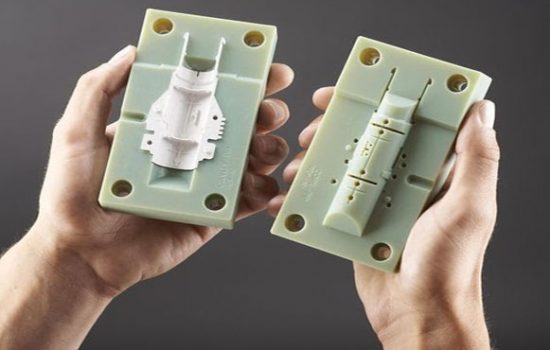

Clamping: The first part of the entire process is securing the mold intended for use through a process called clamping. A mold is usually made of two halves that have to be put together tightly before the injection process begins. This is usually done by a clamping mechanism that is powered by a hydraulic device; the force applied here ensures that no space is left as that will show on the product in the form of lines, and that’s the last thing you would want. The bigger the mold, the longer it takes to clamp things down.

Injection: Raw plastic material that comes in the form of pellets is added into the injection molding machine and then pushed forward to the mold by a special injection unit. The process involves a lot of pressure and heat, and this melts down the pellets into a viscous flowing state that is then quickly injected into the clamped mold once the right temperature has been attained. This is what is called the shot, and the amount is determined by the injection pressure, shot volume, and injection power.

Cooling: Once the molten plastic is safely inside the mold, the cooling process begins immediately, and this is the trickiest part of the entire process. This is the point where things may go wrong if things are not done the right way. As the cooling takes place, the plastic solidifies into the shape of the mold, and if the cooling is not uniform, some undesired shrinkage may lead to one part being deformed. Once some form of solidification has been attained, the clamp can be loosened a little to create room for more air to pass through and accelerate the cooling.

Ejection: Once some sufficient time has elapsed, the cooled mold can now eject the solidified plastic product. The mold is designed with a special mechanism that forces the plastic material out. A mold releasing agent is sprayed around the mold to make detangling much easier. This paper usually takes the longest time, but it is still faster than most of the other processes. Once the ejection is complete, the clamp is shut tight again, ready for the next injection shot.

Source: Pinterest

Injection molding processes are conducted through special machines that are designed just for that purpose and nothing else. They come in varying sizes and shapes depending on the shape of the product you minted to have at the end of the line, but on a general level, they all work using the same principle. The following are the main machines used in this process.

This is the machine used for heating and injecting the material into the mold. The first part of the injection unit is called the hopper, and it is a large container that holds the molten plastic material. It has an open bottom that allows the material to be fed into the barrel that has the mechanism for heating and injecting the molten plastic into the waiting mold. As the molten material moves into the mold, it is further subjected to more heat and pressure, and this is what ensures the molten state is maintained. The injection nozzle is usually narrow, and this ensures the molten plastic is injected into the mold at high pressure quickly before any cooling starts happening. This forces the material to be packed into the mold. Once the obtained amount is attained, the hopper and everything else retracts and close, ready for the next injection.

The mold is what determines the shape of the final product, and for this to happen, the injection gates have to be clamped tight, with no room for air or anything else. It has to be clean and smooth all around to avoid having the final product have grooves and lines that may alter its appearance. The camping process is run by a hydraulic clamping motor that applies maximum pressure to the sides of the mold to ensure that everything is locked in place. Once the nozzle from the injection unit is done, adding molten material and retracts, the cooling process begins immediately. The moment the material has solidified a little, the clamping is eased a little to allow for the cooling process to be a little faster and more evenly spread out.

Source: Pinterest

Good as it may be, the injection molding method has its own flaws alongside the many benefits it brings to the manufacturing world. Where mechanical machines and heat are involved, there are bound to be some mishaps once in a while. The following are the pros and cons of injection molding.

Efficient and Fast Production: It takes a maximum of 2 minutes for a single product to be completed, this may sound like a lot but when you consider the fact that the product comes out ready to use without any need for additions, it becomes impressive.

Cost-Effective: Injection molding is an automated process meaning you don’t require workers to run things. With everything being run by robotics, you don’t have to worry about salaries or compensation in case of an accidental injury.

Flexibility: There’s a lot of design flexibility involved with injection molding. The entire process save for the cooling part involves the use of pressure and heat, and this allows for any changes to be made before solidification is done. The prototype molds can also be switched out to create new shapes when the need arises.

Large Material Choice: As far as raw materials for injection molding are concerned, you have unlimited options to choose from. You can go with thermoplastics, thermosets, or elastomers for plastic products. For metallic products, you have brass, aluminum, steel, among many others.

Consistency: There’s uniformity with injection molding. Using the same mold repeatedly ensures that the end products come out identical with nothing to spare them. This is vital because consistency is what consumers pay attention to.

Reduced Parts: Most times, once the injection molding process is complete, the product is ready to use. There is no need for further processes like polishing or cleaning. A good injection molding system is able to handle everything in 2 minutes.

Enhanced Strength: Products that are made with injection molding are solid and have the highest forms of structural integrity. With reduced parts, this means that lines of weaknesses are eliminated, and this is why injection molded parts are heavily used in automotive industries.

High Tooling Costs: The cost of setting up an injection molding complex is very high. From the number of tools needed, space, and automation, you will need a significant amount of money to get things done.

Part Design Restrictions: There are many restrictions that are imposed on the design capabilities, especially whether plastics are involved. For instance, the mold must have a consistent wall thickness to avoid inconsistencies, and undercuts have to be avoided. All these may prove too much for an automated system.

Not ideal for Small Runs: If you choose to go with injection molding, then you have to be sure of a huge volume of work. Using the process for small work is very costly as the process of cleaning the entire system to accommodate new material is costly.

High Energy Consumption: There’s a lot of heat involved in injection molding, and this translates to very high electricity bills. Running this on a large-scale platform will mean that a good chunk of your profits ends up settling power bills all the time.

Injection molding continues to gain popularity among manufacturers, and this will not stop anytime soon. The future looks very bright for automated processes that incorporate injection molding into the system. Currently, there are many types of molding methods being put into use by a wide range of industries, and more are expected to join that bandwagon in the near future. If you have also been thinking of getting into this wave but have no idea on the right direction to take, check out our website, and you can have all your questions answered by our team of molding experts.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!