Plastic injection molding is a manufacturing process that involves molten plastics being injected into a mold under pressure. The molds are usually metal, the molten plastic is left to solidify and cool forming a plastic item. Several types of plastics are used in this process, however, polyethene either high or low density is the main plastic used. Products obtained this way come in different and complex shapes and are produced in large numbers.

This industry is lucrative since it offers solutions for packaging, medical equipment, construction, automotive and many others. Despite making a lot of profits, their products are cheap and long-lasting. Companies in this industry are spread around the world and in Michigan, they are as follows

It is located in the city of science and technology, Shenzhen, in the south of China. As a molding manufacturer, RYD Tooling was incepted in 2006 and started its operation in producing plastic goods. They have experience in plastic molding, tooling making and design and other operations. They have a working space of 4000 square meters fully equipped with CNC and EDM machines which make it possible to produce 400 sets of tools in a year.

Their capabilities include prototyping, design, injection molding and mold making. Their products are two-shot molds, insert molds, plastic injection molds, large molds, and clear plastic molds. The main industries served by RYD Tooling are automotive, electronics and appliances but are not limited to these only. 90% of their products are exported to Europe and North America.

Source: https://lh3.googleusercontent.com

It was established in 1994 in Mendon manufacturing plastic injection molds. Its facility has an area of 48,000 square feet and includes an injection mold shop, engineering and design shop, an 18 press injection molding machine and a warehouse. They serve industries like medical, plumbing, furniture, pool and automotive, however, they are flexible and can produce any other items.

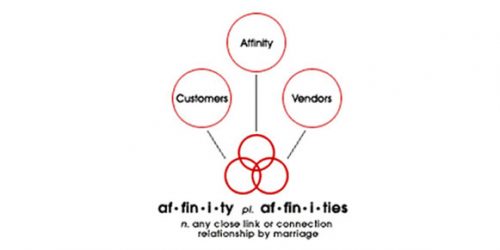

Services at Affinity Custom Molding are tooling, design, planning, production and finalizing of products.

Source: https://res-1.cloudinary.com

Hi-Tech was started 38 years ago in Fraser but relocated to Rochester HIlls in 1987. It is a family-owned business. Their core values are dedication, safety, accountability, quality and customer-focused services. They have grown and established other facilities around the USA and are now considered as leaders in the plastic injection industry. Services at Hi-Tech are plastic injection molding and assembling, design and development, additive manufacturing and CNC machining.

They use modern pieces of machinery in manufacturing to accomplish their goal of quality products for their customers while offering mold testing and tryouts.

Source: www.momentumplatform.com

MSI was started to provide engineering like technical issues and consulting services like sales and marketing to automotive companies. They diversified in 2009 into a plastic injection molding company that makes changes in customer’s products in their newly launched fully equipped factory. They always work as a team to provide and ensure the best services a client can get.

In 2018, they ventured into plastic injection molding fully since the demand was rising and they could not pass that opportunity. Today, other services offered are custom injection molding, prototype injection molding and insert molding.

Source: www.ironwood.com

Ironwood Plastics Inc is renowned for its attainment of difficult projects that require a lot of expertise. It is regarded as a leader not only in Michigan but the whole of the USA in plastic injection molding. CTB Inc, a Berkshire Hathaway industry bought the company in 2010 and currently, have two facilities 60,000 square feet and 25,000 square feet in Ironwood and Two Rivers, Wisconsin respectively.

The military, industrial, automotive and electronics are examples of the industries they serve. Secondary services provided in Ironwood Inc are sonic welding, pad printing, foam in place gasketing, tape and reeling packaging.

Source: https://media-exp1.licdn.com

Located in Saline, they have a 145,000 square feet factory and 70,000 square feet in Monterrey, Mexico and an office in Troy, Michigan. Their specialities are in design and manufacturing with experience of over 35 years. Products in MMI solutions include blow-molding, interior and exterior, components of powertrain and conversions. Services offered are program manager, tool design and construction, full CAE analysis, product design and concept.

In 2014 and 2015, they were recognized and won two awards Top Mold and Tool Maker’s Awards respectively. They have continued leading Michigan and the country at large in plastic injection molding

Plastic injection molding is a big industry and it has been embraced fully across the globe. Plastic products are the most used items globally due to many factors like affordability, durability and lightness. Michigan is one of the leading producers of plastics in the USA and companies found here are very competitive in terms of quality products and cost. This has helped propel the industry ahead hence creating employment opportunities, especially for the youths and contributing to the economic growth of the country.

More inquiries about plastic injection molding can be found on our website at RYD Tooling. We are dedicated to serving you in any aspect of plastic molding and ensure you realize your dream.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!