Plastic injection molding has grown over the last 50 years to become one of the most important manufacturing processes the world has ever known. The flexibility and the range of raw materials that can be used have played a huge role in ensuring that the process can be used for a wide range of products. But how well do you know how plastic injection works?

We are going to look at how plastic injection molding works, the applications the process is used for, and the benefits and limitations associated with the process. If you have been planning to get into plastic injection molding or you are simply curious about the process, then you are in the right place.

What is Injection Molding?

Source:

https://www.pinterest.com/pin/15762667432542502/

This is the process where plastic is used to create a wide range of items and single parts that can be used for domestic and commercial purposes. The process was invented in the early years of the 19th century, but despite being around for that long, there is yet to appear another process that can take over from it.

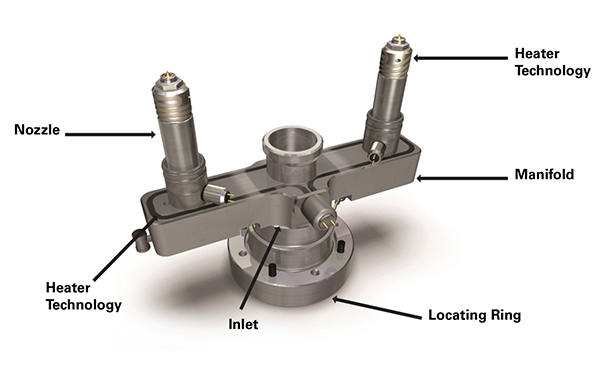

It involved the injection of molten materials through a nozzle in controlled amounts into a mold-shaped crate that determines the final shape of the end product. This allows the manufacturer to create multiple copies of the same item many times over at very first speeds, ensuring mass production is possible and that each copy is identical all through. This is the kind of uniformity that has made injection molding a very attractive prospect for many injection manufacturers who deal with plastic.

How Does Injection Molding Work?

Source:

https://www.pinterest.com/pin/64387469661276568/

The injection molding process is a very straightforward process that begins with the heating of raw materials until they attain a molten state. This is done at very high temperatures, and most of the raw materials are made using all kinds of plastic materials.

Once the molten material attains the right viscosity, it is loaded into the injection machine that ends in a straight nozzle which can be aimed at any part of the mold. The injection cauldron has to be at high temperatures to maintain the molten state of the raw materials; the last thing you would want is for cooling to take place in this part. There is a screw that is set within the melting barrel that allows the right amount of molten materials to enter the injection cauldron.

The injection nozzle is now aimed at the center of the mold, and a precise amount of molten material is injected quickly at a controlled pace, temperature, and pressure. This is to ensure that everything spreads around evenly to aid in uniform cooling. Once the needed amount of molten materials fills up the mold, the injection process is shut off, and the gates are closed.

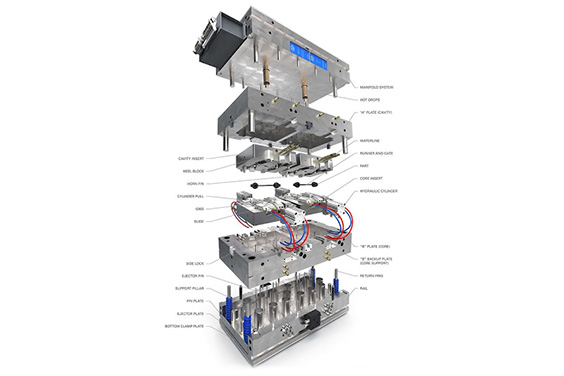

The material is then allowed to cool down slowly and uniformly. This is a very delicate process that can lead to problems if the cooling is uneven, and there are a number of defects that can result from this. Once the cooling process is done, the solidified part is ejected from the mold by specially designed ejectors from below.

Once the part is free of the mold, the injection hooper is lowered again, and a new batch of molten materials is injected into the cauldron for another process. This is repeated over and over again as many times as possible for as many types of materials until the production is done. Every time the part cools to a certain level, the mold opens itself automatically, and the ejector does its work without any assistance or supervision from people.

At no point will the hopper deposit any new material if the part happens to be stuck, something that happens a lot of times due to uneven cooling that may happen. What this means is that the entire process is automated, and it can be set to run on ti snow all night and day, another huge selling point and a reason why it has persisted to this day.

Injection Molding Material List

Source:

https://www.pinterest.com/pin/483996291207044359/

One thing that makes injection molding the ideal process for making plastic products is the fact that it has a wide range of raw materials to choose from. This increases variety in terms of quality and usage. The following are the most common materials being used for injection molding.

- Nylon: This is the most common form of plastic and the easiest to extract from petroleum. It is used to make very hard and durable parts that are mostly used for mechanical components in the automotive and other heavy-duty industries. They are very tough with very high melting points, and this gives the hardness to handle any kind of extreme conditions.

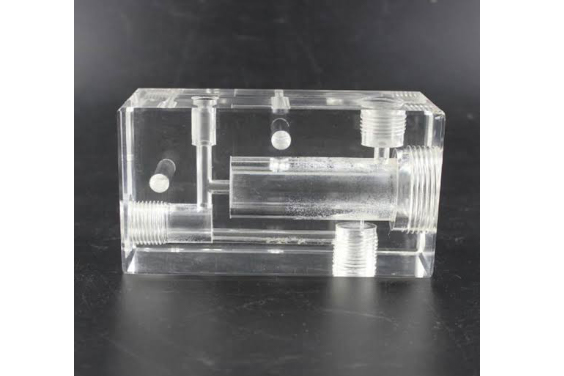

- Acrylic: This is what you go for when you want to make transparent products. They are a good alternative for glass and have a very high tensile strength, and this makes them ideal for making food storage plastic containers that allow people to see the contents before they buy. They are highly resistant, odorless, and don’t contain Bisphenol-A. This is now widely used for food and beverage packaging.

- Polycarbonate: Polycarbonate is another excellent material that boasts of high durability and great aesthetics. It has a uniform mold shrinkage and a precise dimensional control, and this makes it easy to mold the material into any shape you want quite easily. It is stronger than acrylic but not suitable for food storage as it has a very high BPA content.

- Polyoxymethylene: This is an acetal resin that is used for making highly mechanical parts for cars and vehicle types. They are extremely hard and are often used as alternatives for metallic parts in a bid to bring down the weight of the car. Some of the components that are made using Polyoxymethylene include car gears, ball bearings, fasteners, knife handles.

- Polystyrene: Popularly known as PS, this is another heavy-duty material that is used in injection molding to create super hard materials that have a very hard casing. This is called high-impact polystyrene, and it can be seen in the construction of toolboxes. They are one of the cheapest raw materials to use in this process, but they are not friendly to the environment.

- Polypropylene: This is a thermoplastic material that is used for making food packaging containers as it is free of BPA and other harmful chemicals. It is highly flexible and resistant to degradation as it can even be washed in hot water without taking any damage. It also has a very high chemical and moisture resistance and is also elastic, strong, and possesses reliable toughness.

- Polyethylene: Another lightweight material with high chemical resistance that makes for good raw material for injection molding. It is mostly used for making insulation materials for electrical wires and equipment. It is not hard but very supple and flexible, but tearing it apart would be impossible. Other applications include the making of consumer items like milk and medicine bottles, detergent packaging, trash cans, plastic paper bags, among many others.

- Thermoplastic Polyurethane: If you are using a phone with a plastic cover right now, the materials that were used to make that are thermoplastic polyurethane. It is soft, elastic, and highly durable and can be used to make products that imitate rubber-like attributes. It can handle high temperatures and is best suited for power tools, insulating cables, and making sporting goods as well.

- ABS: Acrylonitrile Butadiene Styrene is a very common raw material that is widely used in injection molding factories to make automotive parts mainly. The material is hard, durable, and versatile and is best suited for making protective covers like those used for computers, knives and other tool handles, showerheads, among many others. However, the material is not ideal for making electrical insulation as it has a very low chemical resistance.

Things to Consider when Choosing Raw Materials for Injection Molding

Source:

https://www.pinterest.com/pin/661466264017684757/

When it comes to injection molding, every decision has to be an informed one. The reason is simple; once the mold is set and the materials start rolling in, it would be hard to stop the process. The following should be considered when choosing the raw materials mentioned above.

- Impact Strength: The impact strength determines how the final product will be used for. It has to be higher for parts that will be used as automotive components and lower for regular food packaging materials.

- Water Absorption: This is the percentage of liquid that a material can handle over 24 hours of immersion. A good raw material should be waterproof at best or have the ability to absorb as little of the water as possible.

- Tensile Strength: This is the material’s resistance to tension. This is what helps the final item to withstand any given laid without being pulled apart or collapsing. This is important when making automotive parts.

- Heat Resistance: The final product must have a high melting point, and this is an attribute that is derived from the combination of raw materials used. A higher melting point means that the resulting product can withstand extreme conditions.

Conclusion

Injection molding continues to become integral in the manufacturing world and as technology continues to grow, so are the techniques behind the process. If you are looking to get into injection molding and would like to know the way forward, then check out our website and have all your questions and concerns answered.