Injection molding, one of the most frequently used processes in plastic parts manufacturing today, may enable massive, cost-effective mass production of identical parts. In reality, injection molding is the most cost-effective process for making plastic components in medium to large numbers in the majority of instances. As a result, it is usually favored over other production processes such as CNC machining, urethane casting, and die casting.

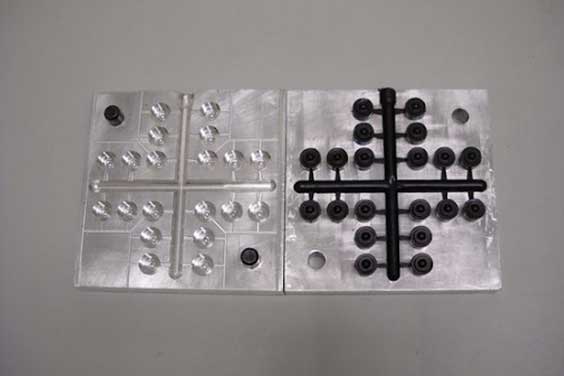

A single-cavity or multi-cavity mold can help in injection molding. Whereas both single- and multi-cavity injection molding techniques need the same fundamental set of actions in the same sequence, the two are often utilized to fulfill distinct demand or timetable constraints and are therefore seldom interchangeable.

Choosing whether to utilize a single-cavity or multi-cavity injection mold is critical to project success. Here are some frequent usage scenarios, as well as their benefits and drawbacks.

The process of injection molding begins with the creation of the mold. The most complicated component of the injection molding process is the mold, which will subsequently be filled with molten plastic to form the required item. Fortunately, it only has to be done once.

Once the mold is created, injection molding becomes a six-step process that can be readily duplicated. The first step is to clamp, or force together, the mold’s two clamshell-like sections. Following that comes injection, in which plastic is heated and injected into the mold. Dwelling and cooling occur next, allowing the plastic to fill the mold and harden. Finally, the mold is opened, and the component is removed using ejector pins.

In its most basic form, a multi-cavity mold is used for producing multiples of the same component. The multiple cavity plastic injection mold is an excellent method to get the most out of your mold base. The cost savings do not just come from faster manufacturing times.

Plastic injection molds in the family tend to be a bit different, but they serve the same purpose. A family injection mold differs in that it creates numerous components that are similar in size/appearance but not identical. These can be used to make plastic pieces for an installation, such as a phone or speaker.

However, one thing to guarantee in this mold frame structure is that all components within the injection mold have comparably sized gating (the line that travels from the flow to the product). This is significant because the cycle periods within the mold must be constant for optimum manufacturing.

Let us first spend some time deciphering the different categories for single and multi-cavity molds in detail.

The injection molding cycle refers to the series of events that occur during the injection molding of a plastic component. When the mold shuts, the cycle begins, and the polymer is injected into the mold cavity. After filling the cavity, a holding pressure is regulated to accommodate material shrinkage.

The number of items you want to mold in a certain timeframe, as well as the cost-benefit, determine whether you require a single or multi-cavity mold. If your goods have a cycle time of one minute, you would never be able to create one million items per year using injection molding using a single cavity mold.

After all, optimizing injection molding takes patience. We also assess how much time it will take to do preventative treatment on the mold. If you want to make a million items each year, you’ll need a multi-cavity mold, such as a four- or eight-cavity mold.

All of our new molds include a shot warranty. It ensures that the mold operates for the shortest possible duration while incurring no expenditures for the customer. Based on the conditions, product design, and tolerances, a single-cavity mold often comes with a shot assurance of one or two million shots. If you want to make many items using the same mold, a multi-cavity mold is a way to go. A four-cavity mold, for example, may produce four million items within the shot guarantee.

Because the procedures of these two molds are so similar, their advantages and disadvantages coincide in many ways. For example, while they will save you money in the long run, they demand a large initial investment due to the lengthier development time required by the mold manufacturer. They also have comparable requirements for your parts, some of which are as follows:

In general, the decision between a single-cavity mold and a multi-cavity mold comes down to time and market demands. When a large number of similar components must be produced in a short time, a multi-cavity mold is generally the preferable option. Multi-cavity molds allow producers to produce more components in less time – an obvious benefit of employing several cavities at the same time.

Multi-cavity molds, on the other hand, aren’t always the ideal choice for a specific project. A multi-cavity mold demands a much larger initial expenditure than a single-cavity mold. Multi-cavity molds are more expensive to produce as they need more materials, effort, and energy than a single-cavity mold.

While investing in a multi-cavity injection mold can undoubtedly pay off when making components in large quantities, at smaller numbers, a single-cavity mold may make better sense.

Multi-cavity molds require a greater lead time since they take longer to produce than single-cavity molds. Furthermore, with multi-cavity molds, maintenance requirements and risk are higher; if one cavity fractures or has a defect, the entire mold might become useless, which can severely influence time-to-market.

It’s always a good idea to know your audience and have a solid grasp of the demand for your goods so you can develop and manufacture to cut costs. This is particularly true in the case of injection molding. Depending on the time and significant cost necessary to make a mold, development teams must do their homework and pick the mold type that best matches the product and market demand.

Luckily, there are injection molding specialists on the market that can advise you on the best route ahead as you select which road to go with your project.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!